Call: 01234 765308

info@liquidengineers.co.uk

liquid engineering requirements.

OIL STORAGE REGULATIONS AND OIL STORAGE TANKS

from Premier Garage Equipment

Lubrication Systems

At PGE, we have decades of combined experience from the very top with our senior management team, right down to our technicians on the ground. It’s rare to find this level of expertise in one organisation, and we’re confident in our ability to deliver.

Lubrication systems can be broken down into several parts. When you partner with PGE, we’ll start by reviewing your current arrangements for oil storage and work with you to ensure that you’re fully compliant in all aspects of oil storage.

Oil storage regulations in the UK

There are strict regulations governing the storage of oil and hefty penalties for anyone found to be in breach of these regulations and for good reason too. Around 17% of all pollution incidents involve oil spillages and most of these are caused by oil leaks from tanks and pipework or from tanks being over-filled.

Government guidance for businesses in England and Wales is provided separately to guidance for Scotland and Northern Ireland. All guidance can be found here. The regulations apply to the storage of oil volumes of 200 litres plus, when stored above ground. They were introduced to reduce oil pollution accidents and to provide a clear set of rules for business owners to follow when storing large quantities of oil. By ensuring you comply with the legislation, you can be confident that you are storing your oil legally, safely and with consideration for the environment.

Choosing oil storage tanks

As an additional precaution, where possible, containers should be positioned well away from areas where vehicles are in use, to avoid collision damage and resulting oil spills.

The most effective method of preventing oil spillage is secondary containment which is outlined in the regulations. A secondary container, commonly a bund or drip tray, must be installed to protect the primary container and its ancillary pipework and equipment. If an oil leak does occur, it can be contained, and hopefully caught in time to prevent a minor incident turning into a major incident.

We always suggest to clients that they sense-check their systems by asking the question: “If this storage container were to burst, where would the contents go and what would be the impact?” By answering that question, you identify inherent hazards present in your set-up.

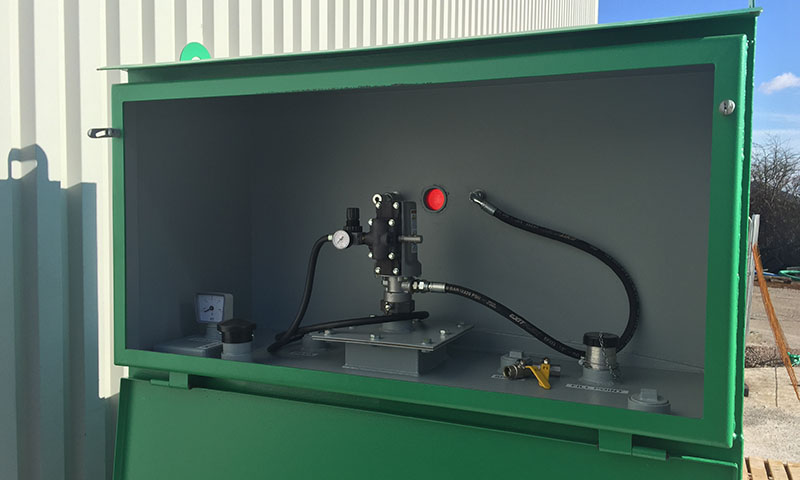

Bespoke oil storage solutions

It’s also possible to stack tanks up to three high if required as this picture illustrates, without compromising compliance.

Oil storage regulation ‘top 10 points to remember’

To make that process quicker and easier, we’ve compiled a top 10 list for our clients, highlighting points from the regulations that you need to know, or take action on.

1. If you have oil storage containers with a capacity of 200 litres or more, you must follow the rules on oil storage.

2. Oil storage containers must be bunded to hold 110% of the capacity of the container volume (or combined volumes).

3. Tanks must be built to BS5410 standards.

4. The tanks or oil containers but be positioned in a safe location with consideration to rivers, underground watercourses, boreholes, storm drains etc.

5. Tanks and containers must be labelled with accurate information about volume and product.

6. Remote filling of tanks (where the delivery driver is not at the tank) must be protected by overfill device or alarm systems.

7. Any possible leakage or dripping must be protected by spill containments or drip trays.

8. All tanks and bunds must be fitted with content gauges.

9. All pumps and pipework should be installed to current standards.

10. Spill protection equipment and procedures must be in place.

How can we help you?

Our work in oil storage is varied and interesting and we partner with a wide range of clients on numerous projects. But what does that look like in practice?

We tend to receive enquiries from a number of sources: oil companies, oil distributors, industry, and directly from end users in multiple applications (e.g. independent garages or franchise workshop dealers).

Let’s take a look at a few client scenarios and how we helped them.

Oil company scenarios

Oil companies also come to us for assistance with issues thrown up by advances in the engineering sector. For example, as engines evolve and become smaller by design and more powerful, oil composition must also evolve (newer engines require thinner higher tech oil). And as new grades of oil are introduced into the market, this impacts on oil tanks and their design/construction. We recently worked with Castrol/BP and one of their customers affected by these changes to reconfigure their oil distribution systems; this involved swapping fluids from one tank to another, updating pipework and ancillary equipment and ensuing that all these changes complied with current regulations.

Garage/ franchise dealer scenarios

Oil Delivery Solutions

Volkswagen UK approached us to work with SEAT in Nottingham, to whom they supplied oil. SEAT already had the required storage tanks in place but were struggling with oil deliveries due to access issues on their property.

We were asked to advise them, and developed a solution designed around remote fill cabinets and remote pipework with an integrated alarm system. Our proposals included the installation of a lock in fill cabinet at the front of the premises with a two inch pipe routed along the side of the building into the oil storage tank.

This design meant that oil tankers could remain on the road while filling the tank remotely (parked on single yellow lines which is permissible when loading and unloading). Ingeniously, we were able to advise the client remotely by using site photos and Google Earth to survey the area, helping to keep costs down.

Oil Compliance Solutions

Another area where we are often asked to support customers is in compliance. You may require guidance to become fully compliant with just a few small changes to processes or equipment. One of the most commonplace faults identified by assessors is single-skin tanks (i.e. not bunded). As we outlined above, the lack of secondary containment can be hazardous if oil leaks or spills.

We can easily identify these issues during a survey visit (for smaller issues, photos and a conversation on the phone can be sufficient), and put a plan in place to rectify them.

Auditors and assessors may request documentation or proof of compliance or your business; at PGE, we are always happy to help you understand what is needed to be compliant and safe at all times. As part of our consultancy service, we provide advice which you follow and as long as you use the recommended equipment and carry out ongoing maintenance, you can be reassured of full compliance.

How are the Oil Storage Regulations enforced?

In England, the Environment Agency is responsible for enforcing these regulations. Remember that compliance is only a snapshot of a moment in time. If you have made changes to your building, or your facilities or equipment are not maintained properly, you may become non-compliant without even realising. And, of course, if a compliance officer identifies an issue, it must be remedied as soon as possible. Failure to act may result in The Environment Agency issuing an Anti-Pollution Works Notice which requires you by law to bring your facility up to the required standard.

A subsequent failure to comply is a criminal act and with environmental concerns growing year by year, the prospect of harsh penalties for non-compliance – including custodial sentences – is a reality and must be taken seriously.

If you’re concerned your oil storage systems may be non-compliant, why not get in touch?

We’re always on hand to advise and guide you through the regulatory framework – and by taking care of what needs doing now, you’ll ultimately save time, money and hassle further down the line.

Call us today

01234 765308 or

Need Some Help?

If you would like to find out more about industrial doors and discuss how Premier can help you, call us on 01234 765308 or complete the form for a call back.