Call: 01234 765308

install and maintenance.

TMS VOLVO CASE STUDY

from Premier Garage Equipment

About our client

Project brief

Maintaining Volvo franchise standards is essential to retaining the franchise and TMS Volvo was keen to ensure the installation of the new equipment proceeded without incident.

To win the business, we had been invited to take part in a competitive tender. Although we were, at the time, already an approved supplier for both Volvo and TMS, there were procurement requirements in place which necessitated a tender.

We were thrilled to be awarded the tender and we believe we did so thanks to our proven experience of working with Volvo dealerships. Our knowledge and understanding of franchise standards are extremely high and we are always focused on attention to detail and quality workmanship.

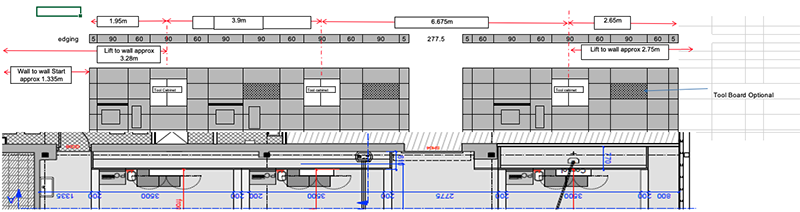

Image shows drawing of wall design for South East facing section of the workshop

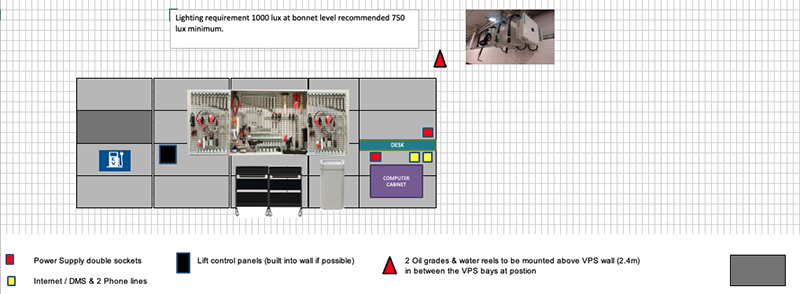

Image shows VPS wall layout with tool station

On this project, the standards we had to adhere to included:

- The layout of the walling system

- Specific dimensions throughout

- Specification of equipment supplied by us e.g. the lifts were carefully specified to allow two technicians to work on each lift requiring a larger than average bay

- Additional air reels also specified

- Locations of central services for air, oil and water

We were set a strict timeframe of 12-16 weeks to deliver the entire project. What’s more, we were not the only contractors on the project, so it was important to schedule our site visits in line with others to ensure the project wasn’t halted unnecessarily. This isn’t something new to us and we have robust project management systems in place to guarantee this aspect of any job runs smoothly.

It also pays to be flexible; no job ever runs to plan 100% and the more adaptable you can be and able to respond when issues arise, the happier the client.

Were there any extras involved in the project?

We were mindful to ensure that any equipment we supplied directly to TMS Volvo matched the corporate colour palette already in place.

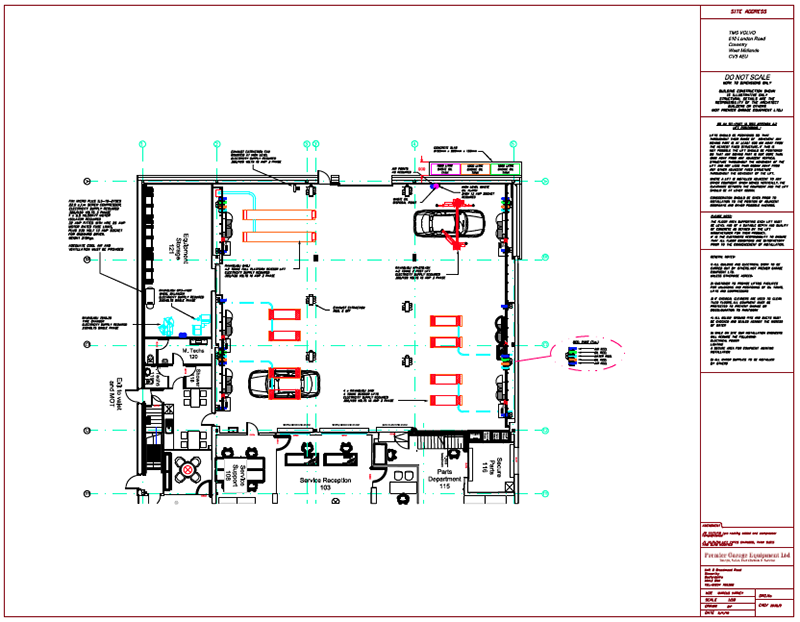

Image shows layout of the workshop including tall equipment and the NW and SE walling systems in place

How we go the extra mile

Our long standing experience of the entire VRE concept immediately gave us an advantage over other suppliers. We always adopt a proactive approach to problem solving; in this case, the VRE concept didn’t naturally fit into the building space, partly due to an extension that took place during the works. This meant the space originally allocated to oil tanks was lost and access to those tanks was restricted. We came up with a solution whereby we manufactured bespoke oil tanks to fit an outside space, providing the same volume but on a smaller footprint.

When it came to lift design, we had to allow for challenging ground conditions due to a high water table. The client’s initial brief included in-ground cassette lifts; however, by working alongside the architect and lift manufacturers, reviewing all options and budgets, we finally agreed upon a combination of 2-post and scissor lifts. Thanks to all the research we conducted, it was clear that in-ground lifts would have been cost prohibitive.

Costs on any project must be carefully managed and we were able to use our skills to re-use the client’s existing equipment where possible, rather than replace with new, without deviating from the Volvo VRE concept. This included alterations to exhaust extraction systems and pipework to air, oil and water.

This is an ideal approach for buildings with existing infrastructure; in a new build, our approach would naturally differ as everything can be designed and supplied to fit perfectly.

What benefits did we bring to the client’s business?

Legal compliance

Thanks to our extensive regulatory knowledge, including LOLER 1998, oil storage regulations, Building Regulations 2010 and the Health and Safety at Work Act, we were able to guide TMS Volvo through the process of ensuring full legal compliance.

Regulations in the UK are complex. It takes time to read them, digest the information and identify the parts relevant to your business. It’s alarmingly easy to trip up and make mistakes without even knowing you’re doing it

Saving space

With careful CAD planning, we maximised the total workshop space using our extensive CAD library and experience. For example, with effective space planning, we ensured that all the lifts and work bays are in the optimum position for efficient and effective use.

Design efficiencies

By designing an environment which puts the right equipment in the right place at the right time – for its intended purpose – you are creating a naturally efficient environment. A good example of this is by installing pumped oil, air and water, exhaust extraction and power into each work bay, which means the technicians does not need to leave the bay to access any of these services.

Increased profit

When all design efficiencies are in place and space-saving concepts are executed, profit naturally follows. As the saying goes, if you fail to plan, you plan to fail.