Call: 01234 765308

info@liquidengineers.co.uk

liquid engineering requirements.

LIQUID ENGINEERING

from Premier Garage Equipment

PGE Liquid Engineering Division

The PGE liquid engineering division deals with the storage, distribution and management of a wide range of liquids and oil products across industry sectors including:

- Passenger cars and vans

- Commercial and public service vehicles

- Industrial

- Agricultural (e.g. tractors, diggers, dump trucks)

- Manufacturing

- Oil

What types of liquid do we deal with?

- Engine oils

- Waste oils

- Gear oils

- Specialist oils

- Antifreeze

- Cutting agents

- Mixing chambers

- Water

- AdBlue

Our experience in liquid engineering dates back many years, since before PGE was even founded, to when Jonathan and Marcus both worked at BP/Castrol (for over 45 years between them). The birth of our liquid engineering division came about thanks to BP/Castrol’s trust in their expertise and the need for them to continue to have access to these services.

Over the years, we have extended our relationships to other oil giants, and are now also approved contractors for Morris Oil, Total, and Volkswagen Oil Programme.

01234 765308

info@liquidengineers.co.uk

We are also specialist consultants on oil storage regulations. If you store oil on your premises, we can help you navigate the complex legislation governing oil storage.

OUR LIQUID ENGINEERING SERVICES

from Premier Garage Equipment

Oil storage & regulations

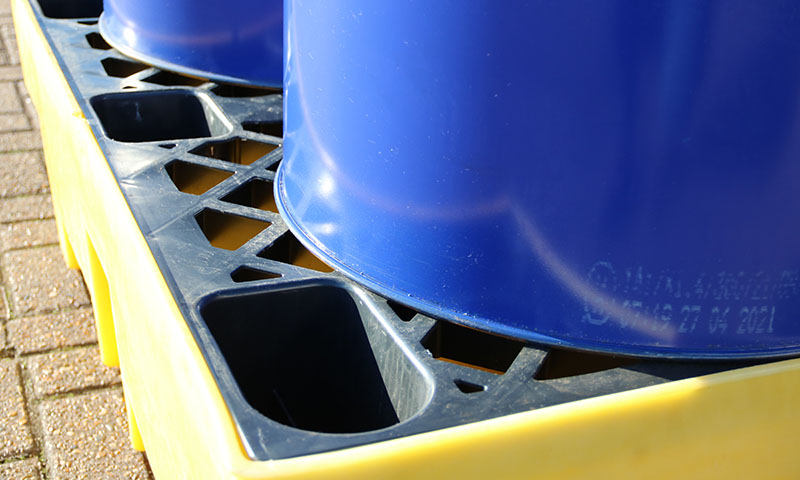

If you’re storing volumes of 200l upwards, you will need to be compliant with the regulations. Secondary containment is the most effective method of safely storing oil and is outlined in the regulations. It usually takes the form of a bund or drop tray and protects the main container, pipework and ancillary equipment.

01234 765308

info@liquidengineers.co.uk

Oil storage tanks

We can design a tank to suit any space, be it tall and square, long and narrow or short and wide. We can also customise the size and number of inlet and outlet ports for your tanks. And finally, we can provide cabinets which house all ports and pumps to protect them from the weather while also keeping them secure.

01234 765308

info@liquidengineers.co.uk

Fluid dispensing

We can design a bespoke system for you according to the demands of your workshop. There are a range of components which we use to create these tanks including specialist pumps, alarms, pipework, distribution mechanisms and meters etc. All our systems are carefully calibrated to minimise tolerances and dispense according to current ‘weights and measures’ standards.

01234 765308

info@liquidengineers.co.uk

Oil monitoring

Keeping track of your inventory is crucial to business success. A fluid management system helps you to account for every drop of fluid. Who used it? How much did they use? Which job (and customer) did they use it for?

With tanks holding thousands of pounds worth of fluids, having accurate records of how that fluid is used helps you to stay in control.

Our fluid management systems provide a host of benefits including:

- Delivery of product according to ‘weights and measures’ standards

- Real-time stock management

- Invoice accuracy

- Automated ordering

- Alarm notifications

- Total security

- Peace of mind

01234 765308

info@liquidengineers.co.uk

Drum/barrel equipment

Barrels are growing less and less popular due to low capacity, resource management and their environmental impact. We can recommend the right drum equipment to meet your needs, and offer drum handling services should you need them.

01234 765308

info@liquidengineers.co.uk

Oil spill management

Prevention is always the preferable option but if spills do occur, we can ensure you’re in the best possible position to handle them. We can provide spill management kits containing a range of equipment to clean up the leaks as soon as possible and dispose of them quickly and safely.

01234 765308

info@liquidengineers.co.uk

Waste oil management

Each year, we deal with hundreds of waste oil spillages caused by an inadequate waste management system. These include the wrong tank design, no alarm systems to monitor tank levels or alarms which malfunction due to lack of maintenance. No-one wants to deal with waste oil spillages – they are expensive to clear up and can cause a great deal of damage.

01234 765308

info@liquidengineers.co.uk

HOW TO STORE OIL CORRECTLY

from Premier Garage Equipment

How to store oil correctly

Oil storage is strictly regulated by DEFRA (the Department for Environment, Food and Rural Affairs) to guarantee public and personal safety. It’s also important to follow these rules to avoid possible environmental damage and contamination. Commercial premises with storage capacity for 200 litres of oil upwards are subject to the legislation.

Oil must be stored in specific containers such as a drum, bunded tank or bowser. You must carry out a risk assessment and if your storage facility is deemed to be high risk, you will also be required to provide secondary containment around the primary storage. Factors likely to increase your risk include proximity to rivers, lakes and other waterways; proximity to open drains; and proximity to water sources such as wells and springs.

Whatever you use oil for, be it as fuel for vehicles or power, full compliance at all times is required, or you could face prosecution. Regular inspection and maintenance of oil tanks is addressed in the legislation as well as design requirements for tanks, which must meet current British Standards.

You’ll also need to check that you are compliant in other areas such as where tanks are located on your premises, tank security and any oil delivery mechanisms you have in place.

01234 765308

info@liquidengineers.co.uk

Are you truly confident you know everything you need to know about liquid engineering?

With hundreds of products on the market all making bold claims about performance and quality, plus the government oversight of oil storage, there’s a lot to remember and evaluate. If you’re not sure where to start, why not get in touch with us today to find out more?

Call us today

01234 765308 or

Related Liquid Engineering Services

All of our services go hand-in-hand, you may also require our help with:

Liquid Engineering Design & Installation

Liquid engineering systems are a core component in many industrial settings. How you store, handle and manage liquids on your premises can affect security, safety of employees, productivity and profitability. Need help getting the design and installation of your liquid engineering services right?

Liquid Engineering Aftersales

Garage Equipment

Sourcing the right equipment for your workshop can be crucial to the success of your business. We can take care of anything garage-related, from brand new builds to workshop redesigns, from new MOT bays to lifts, wheel and tyre equipment and more.

Industrial Doors

Are you in the market for an industrial door or automated gate? As DHF members we have built a strong reputation with a wide range of customers supplying and installing doors and gates on commercial premises across the UK. Considering a new purchase?

Need Some Help?

If you would like to find out more about industrial doors and discuss how Premier can help you, call us on 01234 765308 or complete the form for a call back.

What Our Customers Say